Understanding Consignment Tracking in OM Logistics

Consignment tracking in OM logistics is a crucial aspect of supply chain management that ensures the smooth flow of goods from the manufacturer to the end consumer. By keeping a close eye on consignments, businesses can optimize their operations, reduce costs, and enhance customer satisfaction. In this detailed guide, we will explore the various dimensions of consignment tracking in OM logistics, providing you with a comprehensive understanding of how it works and its benefits.

What is Consignment Tracking?

Consignment tracking refers to the process of monitoring the movement of goods from one location to another. It involves the use of technology, such as GPS, barcodes, and RFID, to track the consignment’s journey and provide real-time updates to the relevant parties. This process is essential in ensuring that goods are delivered on time and in good condition.

Key Components of Consignment Tracking

Consignment tracking in OM logistics involves several key components, including:

-

Barcode and RFID Technology: These technologies are used to identify and track consignments throughout their journey. Barcodes are typically used for smaller items, while RFID tags are more suitable for larger consignments or those that require frequent scanning.

-

GPS Tracking: GPS technology allows businesses to monitor the location of consignments in real-time, providing accurate information on their whereabouts.

-

Transportation Management Systems (TMS): TMS software helps businesses manage their transportation operations, including consignment tracking, route optimization, and carrier selection.

-

Warehouse Management Systems (WMS): WMS software helps businesses manage their warehouse operations, including inventory management, picking, and packing.

Benefits of Consignment Tracking

Consignment tracking in OM logistics offers several benefits, including:

-

Improved Visibility: Consignment tracking provides real-time visibility into the movement of goods, allowing businesses to make informed decisions and respond quickly to any issues that may arise.

-

Reduced Costs: By optimizing transportation routes and reducing the risk of lost or damaged goods, consignment tracking can help businesses reduce their logistics costs.

-

Enhanced Customer Satisfaction: Consignment tracking ensures that goods are delivered on time and in good condition, leading to increased customer satisfaction.

-

Increased Efficiency: By automating the tracking process, businesses can save time and resources, allowing them to focus on other critical aspects of their operations.

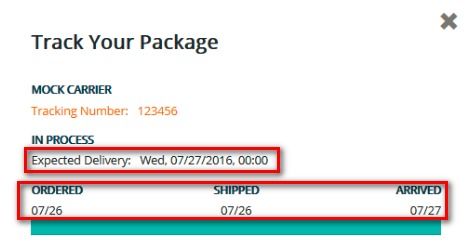

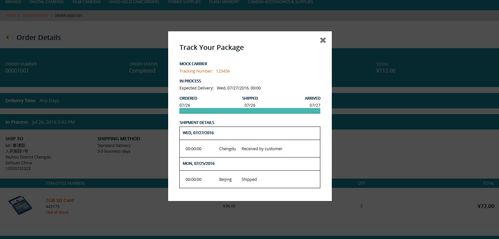

How Consignment Tracking Works

Consignment tracking in OM logistics typically involves the following steps:

-

Goods are packed and labeled with a barcode or RFID tag.

-

The consignment is scanned and recorded in the TMS or WMS.

-

The consignment is loaded onto a transportation vehicle, and its location is tracked using GPS technology.

-

The consignment is delivered to the destination, and the delivery is confirmed.

-

The consignment is unloaded, and the delivery is recorded in the TMS or WMS.

Challenges in Consignment Tracking

While consignment tracking offers numerous benefits, it also comes with its own set of challenges, including:

-

Complexity: Consignment tracking involves multiple systems and processes, which can be complex to manage.

-

Cost: Implementing and maintaining a consignment tracking system can be expensive, especially for small businesses.

-

Data Security: Ensuring the security of consignment tracking data is crucial, as sensitive information may be involved.

Best Practices for Consignment Tracking

Here are some best practices for implementing and managing a consignment tracking system in OM logistics:

-

Choose the Right Technology: Select a consignment tracking system that meets your business needs and integrates well with your existing systems.

-

Train Your Employees: Ensure that your employees are trained on how to use the consignment tracking system effectively.

-

Monitor and Analyze Data: Regularly monitor and analyze consignment tracking data to identify areas for improvement.