Alpha Om 353 Solder Paste Datasheet: A Comprehensive Overview

When it comes to selecting the right solder paste for your electronic assembly needs, the Alpha Om 353 solder paste datasheet is a valuable resource. This datasheet provides a detailed look at the properties, application, and performance of the Alpha Om 353 solder paste. In this article, we will delve into the various aspects of this datasheet to give you a comprehensive understanding of what makes Alpha Om 353 stand out in the market.

Material Composition

The Alpha Om 353 solder paste is composed of high-purity, lead-free solder balls, flux, and other additives. The solder balls are made of a tin-silver-copper (Sn96.5Ag3.0Cu0.5) alloy, which offers excellent wetting and reflow characteristics. The flux used in this paste is a no-clean, water-soluble type, ensuring minimal residue and environmental impact after reflow.

Physical Properties

Here are some of the key physical properties of the Alpha Om 353 solder paste:

| Property | Value |

|---|---|

| Solder Ball Size (micron) | 25-45 |

| Viscosity (cP) | 100-150 |

| Thermal Conductivity (W/mK) | 0.025 |

| Specific Gravity | 7.5 |

Application and Performance

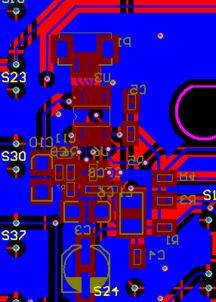

The Alpha Om 353 solder paste is designed for use in a wide range of applications, including surface mount technology (SMT), ball grid array (BGA), and fine-pitch devices. It is suitable for both manual and automated assembly processes. The paste’s excellent wetting and reflow characteristics ensure reliable joints and minimal voiding, even on complex boards.

Here are some of the key performance aspects of the Alpha Om 353 solder paste:

| Performance Aspect | Description |

|---|---|

| Wetting | Excellent wetting on various substrates, including copper, nickel, and gold |

| Reflow Profile | Wide reflow temperature range, allowing for flexibility in process development |

| Joint Reliability | High joint strength and excellent resistance to thermal and mechanical stress |

| Voiding | Minimal voiding, even on complex boards with fine-pitch components |

Handling and Storage

Proper handling and storage of the Alpha Om 353 solder paste are crucial for maintaining its quality and performance. Here are some guidelines to follow:

- Store the paste in a cool, dry place, away from direct sunlight and extreme temperatures.

- Keep the container tightly sealed when not in use.

- Use the paste within the recommended shelf life, which is typically 12 months from the date of manufacture.

- Follow the manufacturer’s instructions for mixing and applying the paste.

Conclusion

The Alpha Om 353 solder paste datasheet offers a wealth of information about this high-quality product. By understanding its material composition, physical properties, application, and performance, you can make an informed decision when selecting the right solder paste for your electronic assembly needs. Remember to follow the handling and storage guidelines to ensure the paste remains in optimal condition for use.